1. Automatic Spraying Equipment Factory Components and Technology

Automatic Spraying Equipment Factory produce advanced systems featuring robotic arms, precision nozzles, programmable controllers, and IoT-enabled sensors. These devices ensure uniform material distribution, reduce waste, and integrate seamlessly into smart manufacturing lines. High-end models include adaptive pressure controls and real-time diagnostics for optimal performance.

2. Key Applications of Automatic Spraying Equipment Factory Systems

Industries like automotive, aerospace, agriculture, and construction rely on automatic spraying systems for tasks such as painting vehicles, coating machinery, disinfecting surfaces, and applying pesticides. Their accuracy and speed make them ideal for high-volume production and complex geometries.

3. Cost Analysis of Automatic Spraying Equipment Factory Machines

Entry-level systems start at 15,000,whilefullyautomatedindustrialsetupsexceed250,000. Pricing depends on automation level, payload capacity, and customization. Mid-range options (50,000–120,000) balance affordability with features like multi-axis mobility and cloud-based monitoring.

4. Best Practices for Operating Automatic Spraying Equipment Factory Units

Calibrate spray patterns based on material viscosity and surface type. Use pre-programmed settings for repeatable tasks. Perform routine maintenance, including nozzle cleaning and lubrication. Store chemicals in temperature-controlled environments to maintain efficacy.

5. Selecting the Ideal Automatic Spraying Equipment Factory System

Assess production scale, material compatibility, and workspace layout. Prioritize systems with modular designs, easy-to-upgrade software, and compliance with industry standards (ISO, OSHA). For hazardous environments, choose explosion-proof or corrosion-resistant models.

6. Safety Protocols for Automatic Spraying Equipment Factory Operations

Operators must wear PPE, including respirators and protective suits. Install anti-static mechanisms to prevent ignition risks. Ensure proper ventilation and conduct regular electrical inspections. Implement emergency shutdown protocols and staff training programs.

7. Design Advantages of Modern Automatic Spraying Equipment Factory Systems

Innovative designs focus on energy efficiency, reduced overspray, and ergonomic controls. Lightweight robotic arms minimize operational fatigue, while AI algorithms optimize spray paths. Sustainable models minimize solvent emissions and support eco-friendly manufacturing.

8. Automatic Spraying Equipment Factory FAQs

Q: How to troubleshoot uneven spray coverage?

A: Check nozzle alignment, pressure settings, and material consistency.

Q: Can automatic sprayers handle flammable coatings?

A: Yes, select ATEX-certified systems with spark-resistant components.

Q: What industries benefit most from automatic spraying equipment?

A: Automotive, electronics, and agriculture due to precision demands.

Q: How long do automatic spraying systems typically last?

A: 10–15 years with regular maintenance and timely part replacements.

Q: Are these systems compatible with water-based materials?

A: Absolutely—ensure pumps and hoses are designed for low-viscosity fluids.

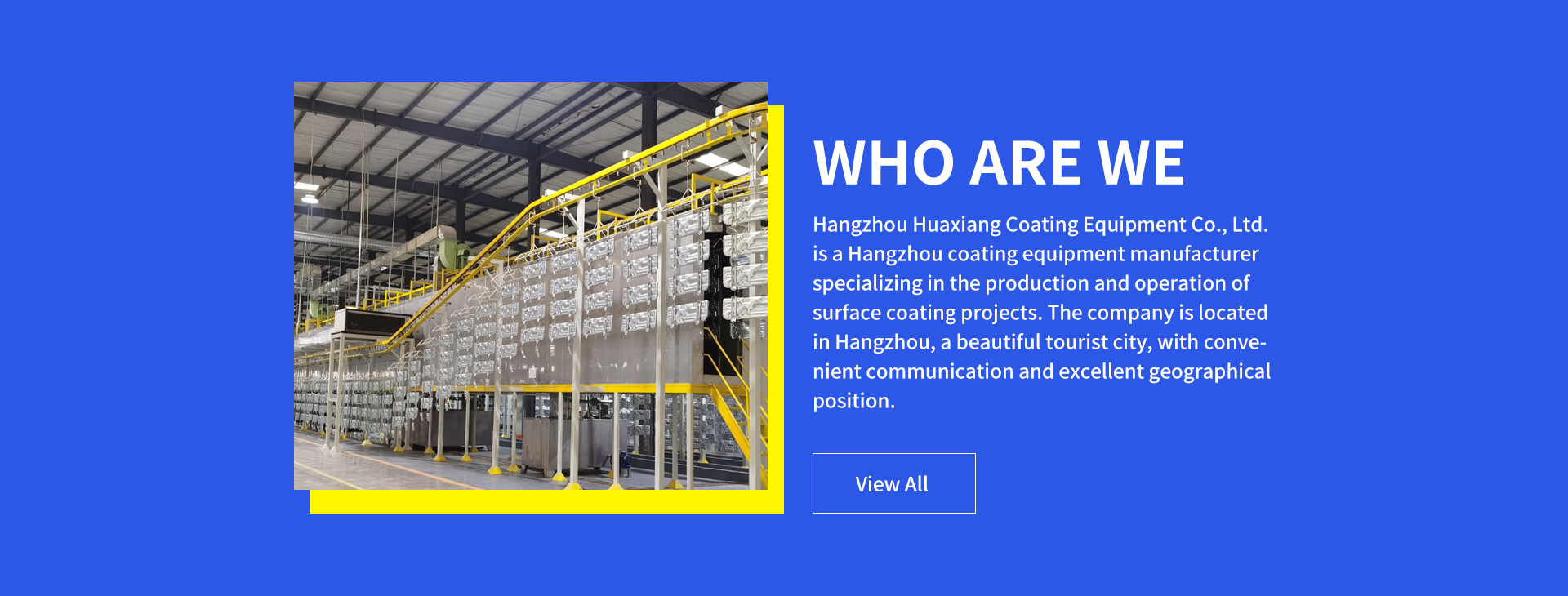

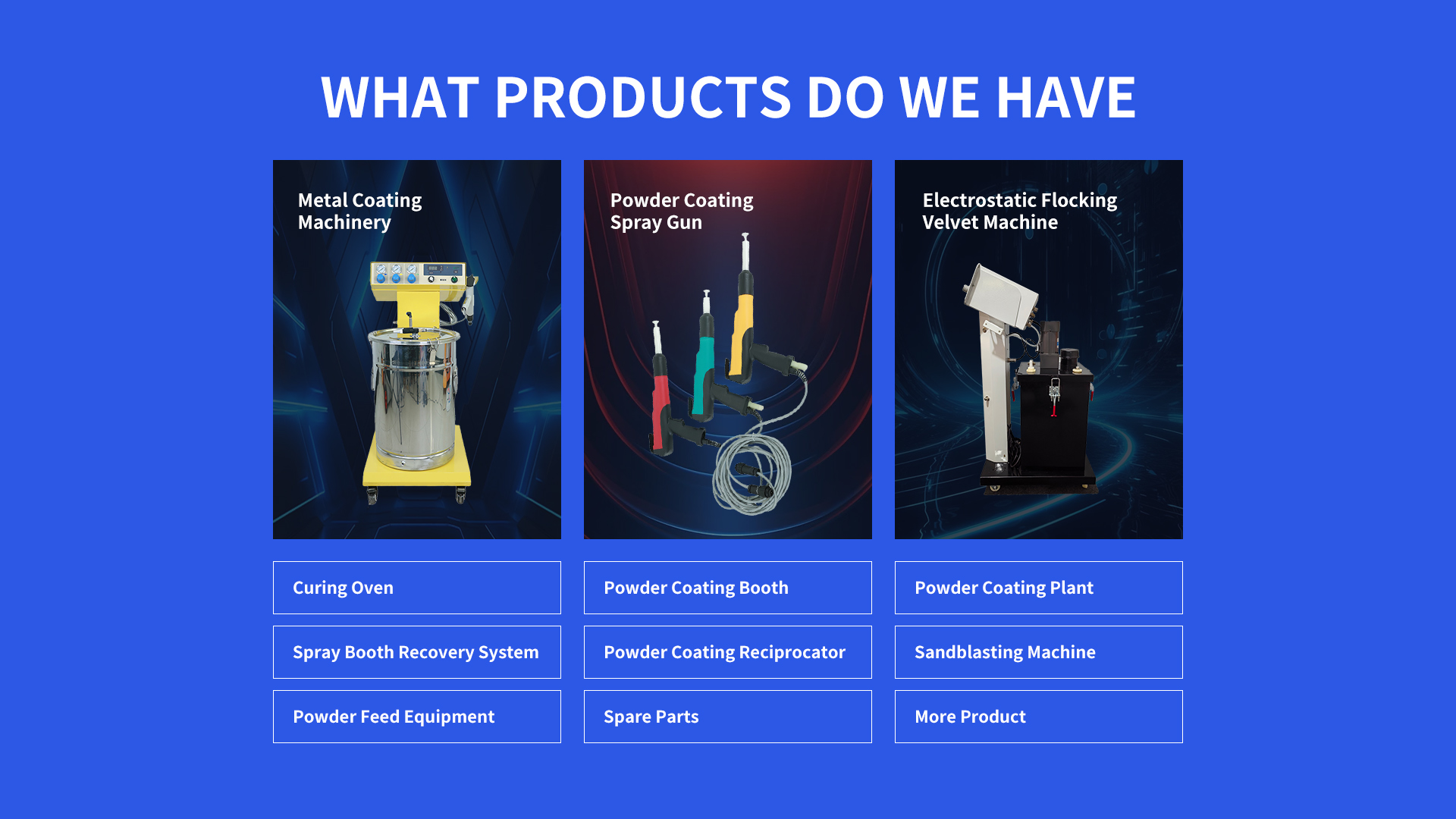

Disclaimer: Enhance your coating process with advanced electrostatic powder coating machines, precision powder coating spray guns, comprehensive powder coating systems, and efficient powder coating lines from Hangzhou Huaxiang Coating Equipment Co., Ltd. Designed for reliability and high-quality finishes, our solutions meet all your industrial powder coating machine needs. Contact us at sale3@cncolourspray.com