In the realm of powder coating, the

Industrial Powder Coating Machine stands as an indispensable cornerstone, serving as the key to attaining exquisitely high - quality finishes that redefine the standards of surface perfection.

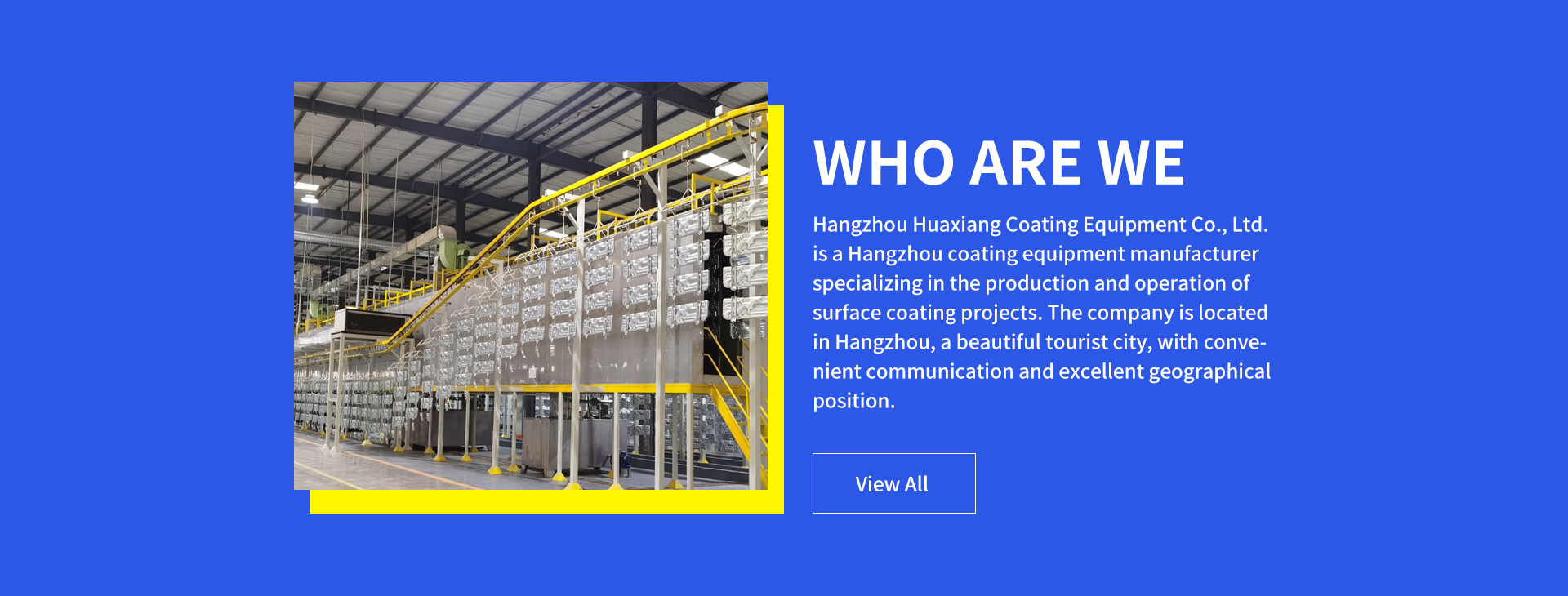

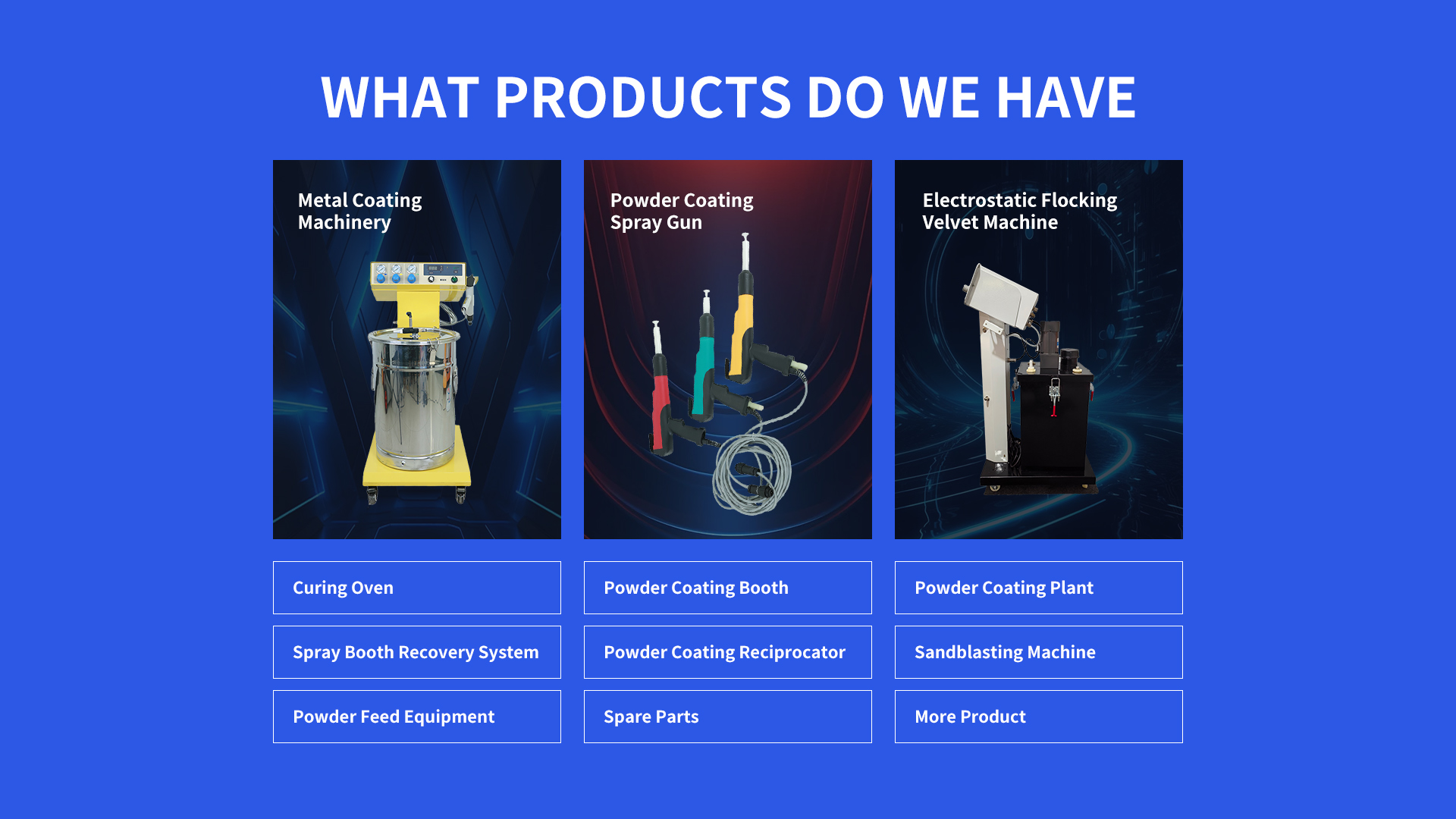

The Industrial Powder Coating Machine, a paragon of engineering marvel, presents a harmonious blend of complexity and efficiency. At its core lies a powder - feeding system, often accompanied by a capacious hopper, acting as a reservoir for the powdered coating material. A sophisticated metering device meticulously governs the flow of powder, ensuring precision in every application. The spray gun, an elemental component, assumes a pivotal role. In electrostatic models, it bestows an electrostatic charge upon the powder, thereby enhancing its adhesion to the workpiece with an almost magnetic affinity. Complemented by a user - friendly control panel, operators are empowered to fine - tune an array of parameters, including powder flow rate, electrostatic voltage, and spray pattern, with remarkable ease. Moreover, in the echelons of advanced technology, certain machines are outfitted with a powder - reclaim system, featuring cyclones or filters, which elegantly recycle over - sprayed powder, minimizing waste and maximizing resource utilization.

Automotive manufacturing plants, the cathedrals of automotive innovation, harness the power of these machines to adorn car bodies, parts, and wheels. The result is a finish that not only exudes a sleek allure but also endures the rigors of time and usage, ensuring durability in the face of the most demanding conditions. Metal furniture factories, too, rely on these machines to transform large - scale metal frames. The powder coating not only enhances the aesthetic appeal but also fortifies the furniture, making it a paragon of both beauty and resilience. Industrial machinery production facilities, in their quest to safeguard and beautify large - scale equipment, find solace in the

Industrial Powder Coating Machines. These machines act as a shield, protecting the equipment from the ravages of the environment while bestowing upon it a visual splendor that commands attention.

Embarking on the journey of acquiring an

Industrial Powder Coating Machine, one is met with a spectrum of options, each with its own price tag. Basic

Industrial Powder Coating Machines, tailored for small - scale industrial undertakings, grace the market with a price range of approximately $3000 - $8000. Their simplicity is their charm, with uncomplicated features and a fundamental powder - feeding system that gets the job done. Mid - range machines, on the other hand, offer a step up in sophistication. Equipped with superior - quality components and more advanced control capabilities, they are priced between $8000 - $15000. For those who seek the zenith of industrial - grade technology, high - end machines await. Adorned with state - of - the - art features such as automated powder - reclaim and precise electrostatic control, these machines can command a price upwards of $15000, promising a return on investment in the form of unrivaled performance and efficiency.

Before commencing the powder coating odyssey, a meticulous inspection of all connections is imperative. Ensure that the powder - feeding system is replete with the appropriate powder, a crucial step in setting the stage for a seamless operation. The control panel, a veritable command center, should be calibrated according to the unique requirements of the workpiece. During the spraying process, the spray gun should be held at a consistent distance and angle from the workpiece, a technique that ensures an even and flawless coating. Once the task is complete, the powder - feeding system and the spray gun must be cleansed to prevent the accumulation of powder, preserving the integrity and functionality of the equipment.

Navigating the labyrinth of selecting the right

Industrial Powder Coating Machine requires a strategic approach. First and foremost, consider the magnitude of your production volume. High - volume production demands a machine with a high - capacity powder - feeding mechanism and an efficient powder - reclaim system, ensuring a continuous and cost - effective operation. Next, evaluate the diverse types of workpieces that will pass through your production line. Complex shapes may necessitate a machine with adjustable spray patterns, allowing for a customized coating solution. Finally, establish a budget that aligns with your long - term production aspirations. A well - thought - out budget not only ensures a wise investment but also paves the way for sustainable growth.

Safety, the cornerstone of any industrial operation, should never be compromised. When working with industrial powder coating machines, don a dust mask to shield your respiratory system from the fine powder particles that may become airborne. Safety goggles and gloves are equally essential, protecting your eyes from potential splashes and your hands from contact with the powder. In electrostatic models, ensure proper grounding to prevent the occurrence of electrical accidents, a precaution that can safeguard both lives and equipment. Additionally, maintain a clean work area, free from flammable materials, to minimize the risk of fire hazards.

The powder - reclaim system, a testament to engineering ingenuity, serves as a cost - saving measure by reducing material waste. The ability to recycle over - sprayed powder not only conserves resources but also contributes to a more sustainable production process. Precise control over powder flow and spray pattern is the secret sauce behind achieving a high - quality finish. This level of precision ensures that every workpiece is coated to perfection, meeting and exceeding the highest standards of quality. The overall design of the industrial powder coating machine is optimized for efficient operation, resulting in increased productivity and a shorter turnaround time.

Q: What if the powder coating is uneven?A: Embark on a diagnostic journey by examining the spray gun's distance from the workpiece and the powder flow rate. Adjust these parameters with precision, as if you were fine - tuning a musical instrument, to rectify the uneven coating.Q: Can I use different powder types?A: Yes, you can traverse the landscape of different powder types. However, between each change, ensure that the powder - feeding system is thoroughly cleansed, leaving no trace of the previous powder, to prevent contamination.Q: How often should I clean the powder - reclaim system?A: To maintain its efficiency, cleanse the powder - reclaim system every few uses. Think of it as a regular tune - up for your machine, ensuring that it operates at its peak performance.Q: What if the machine stops working during operation?A: Conduct a systematic check of the power supply, connections, and the control panel for error messages. It's like solving a puzzle, piece by piece, to identify and resolve the issue.Q: Can I upgrade the control panel of the machine?A: It might be a possibility, a glimmer of hope for enhancing your machine's capabilities. Reach out to the manufacturer and engage in a dialogue to explore compatible upgrades.